A blueprint design for delivering equivalent storage

The CENTAUR® blueprint solution can be rapidly adapted to any location based on standard design settings, with a simple modelling process demonstrating benefit. Standard components shorten the delivery timescale and working closely with design and build partner can deliver and commission a system in a matter of weeks.

Dynamic Local Control Hardware – standard components, simple application

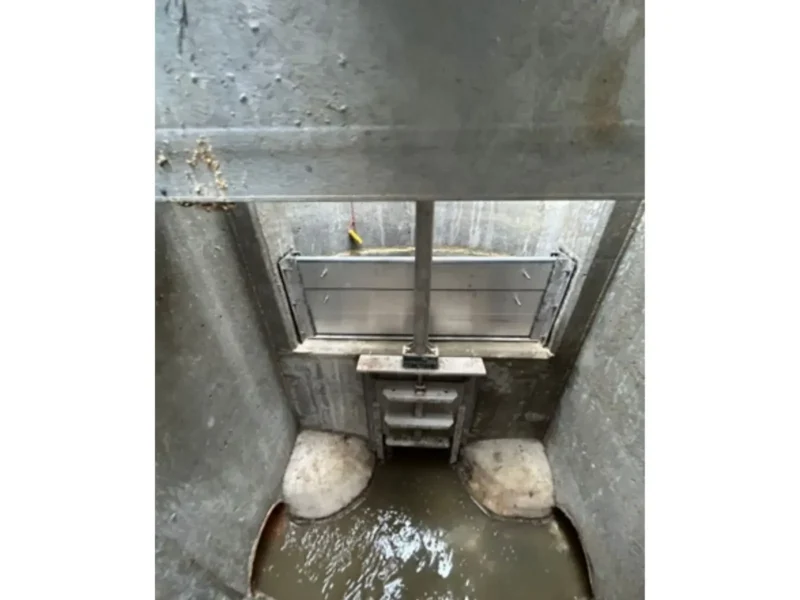

The key ‘in network’ elements of the CENTAUR® system are well known: an on-seat actuated penstock which controls the dynamic storage, attached to a weir wall which provides the mechanism to create the maximum available equivalent storage volume.

From a blueprint design perspective, these standard elements can all be installed into a ‘standard’ manhole, allowing a rapid design process, minimising time to site and rapidly delivering benefit.

All of the key parameters of this design are developed within the modelling environment and the performance is tested to confirm both system behaviour and benefit realised. So modelled behaviour = real world behaviour.

CENTAUR® System Hardware – delivering Sense-Think-Act

Level information from the target storm overflow and from behind the penstock provide the key information into the CENTAUR® system.

A local kiosk houses the CENTAUR® HUB which drives the Sense-Think-Act behaviour, providing control instructions through to the actuator which controls the penstock behaviour.

All of this is part of a self-contained, cyber secure CENTAUR® system housed in a WIMES approved roadside kiosk. This enables additional client telemetry interfaces, battery back-up options and bespoke upgrades to be locally contained.

Phase 1 – Opportunity Mapping

Dynamic Equivalent Storage – Finding the Opportunities

Identifying where CENTAUR® can be of benefit is an important first phase of implementing the blueprint solution. We can work with you to rapidly identify equivalent storage opportunities to integrate CENTAUR® into networks, helping you to deliver capital and carbon-efficient solutions to the storm overflow challenge.

To enable rapid benefit testing and deployment of CENTUAR®, an up-front understanding of where there is potential for equivalent storage is crucial. CENTAUR® Opportunity Maps provide this, enabling a rapid benefit assessment and transition to modelling to demonstrate this benefit.

Storm Overflow Focus – what could be achieved with CENTAUR®?

Utilising simple outputs from existing hydraulic models, it is easy to identify where the conveyance system can be enhanced as a spill occurs at a storm overflow. It is then possible to determine how flow can be managed behind penstocks located upstream of storm overflows, creating an equivalent storage volume. This process is repeated throughout the catchment, identifying where pockets of equivalent storage could be created to provide accurately quantified benefit.

The Opportunity Map – rapid system visualisation

With a simple geospatial output, dynamic storage opportunities can be rapidly compared with storage/benefit performance requirements for storm overflows, prioritising opportunities to take through to modelling and system installation. If the volume meets the need, dynamic equivalent storage using CENTAUR® is the rapid, low cost, low carbon solution.

Phase 2 - Modelling CENTAUR® Benefits

Demonstrating Benefit – “Model Behaviour = Real World Behaviour”

The CENTAUR® control algorithm that drives the dynamic system behaviour within live installations has been included within InfoWorks ICM, the UK industry standard software for the development of wastewater network interventions. This means that the creation of equivalent storage using CENTAUR® can be accurately demonstrated and quantified in the same environment as traditional grey/green solutions. This means that ‘model behaviour = real world behaviour’ providing a unique opportunity to rapidly demonstrate performance benefits strategically as part of a storm overflow reduction programme.

Simple Set Up – rapid results

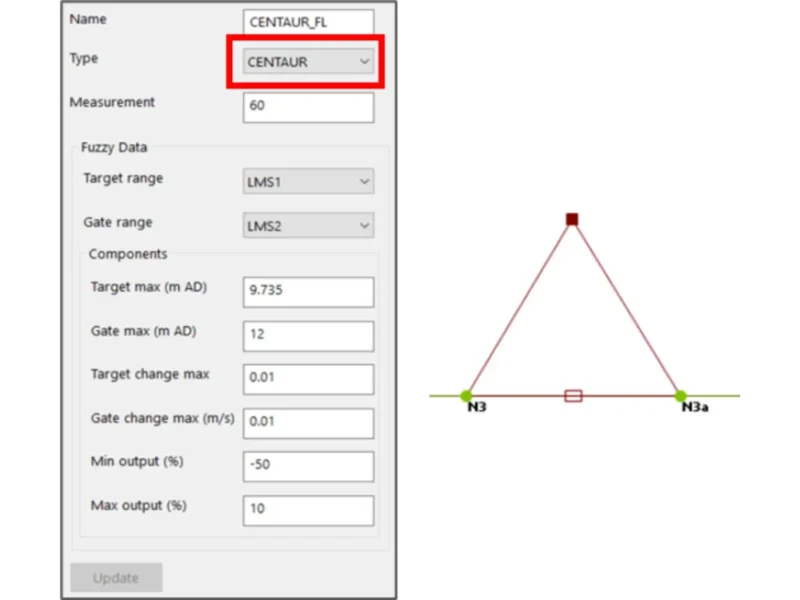

CENTAUR® ‘in network’ hardware is quite simple: it is an actuated penstock fixed to a weir wall in a manhole. This simplicity is replicated within the modelling environment.

Introduce a variable speed gate and a weir within a manhole within the model, and that is representative of the hardware in the network.

The CENTAUR® controller is then applied to the gate using the real time controller type ‘CENTAUR®’ and setting the system up to protect the storm overflow. This controller contains the algorithms.

This process can be completed in as little as 20 minutes, meaning the CENTAUR® system can be rapidly integrated into a catchment model based on the blueprint and performance benefit tested, allowing equivalent storage to be identified as an upfront quick win intervention at storm overflows.

One or More – systems in series or in parallel

With the objective of protecting a storm overflow, the creation of equivalent storage with CENTAUR® is targeted where it can deliver benefit, but it doesn’t need to be a single penstock. Multiple installations can be tested and installed to deliver the required performance improvement. CENTAUR® systems can be installed to operate in series or in parallel to provide multiple opportunities to deliver performance improvements at storm overflows. If you can model it, CENTAUR® can deliver it.

Phase 3 - Installation

CENTAUR® End to End – A Collaborative Delivery

Working with clients and contractors, the blueprint design becomes site specific. Modelling parameters are implemented within CENTAUR® and the installation manhole is specified. We work with the team throughout the process, supporting with our understanding of design aspects and working with stakeholders through to commissioning.

Optimised Workflows – Delivery to Programme

Our internal procurement and manufacturing processes mean that we can construct and test CENTAUR® systems in house in advance of the critical path, so we can always install to meet the contractor programme. Parts of the system can be free issued early to enable optimised activities, with focussed installation activities enabling go-live.

Stakeholder Adoption – Learning and Development

Part of our approach is to work with our clients to embed knowledge of the system with internal stakeholders. This can involve training and development of local operations teams on all required aspects of CENTAUR®, enabling them to undertake maintenance activities. The Cura Terrae team then provide wrap-around maintenance, ensuring system operation and continued optimisation of storm overflow performance.